Bonding Rubber to Metal

Anti-vibration mounts and shock mounts incorporating both metal and rubber can be constructed either by bonding the rubber to the metal or by attaching the rubber component to the metal component through mechanical means.

Anti-vibration mounts and shock mounts incorporating both metal and rubber can be constructed either by bonding the rubber to the metal or by attaching the rubber component to the metal component through mechanical means.

There are numerous reasons why controlling vibrations in construction work is important, including the need to keep the construction plans continuing without complaint from the public.

Most machinery experiences a level of vibration, and will have an expected ‘normal’ range of machine vibration while functioning. However, over time, or if something breaks or goes wrong, this level of vibration may be elevated beyond what is expected, and this can easily become dangerous to operators and the machine itself.

In 2019, Dacorum Borough Council was fined £100,000 after seven workers developed Hand Arm Vibration Syndrome. The investigation found that the council had failed to identify risks associated with the use of certain power tools and excessive use had resulted in the condition.

In the modern age, with our ever-increasing environmental awareness, it’s no wonder that different types of renewable energy and power generation are thriving. In the UK, one of the most popular forms of renewable energy is wind farms, both on- and off-shore, but the vibrations and noise from wind farms can be prohibitive in their building.

Air source heat pumps vs ground source heat pumps; the debate continues between these two similar but distinct technologies. Between May and July 2022, almost 903 ground and air source heat pumps were used to displace other types of home heating fuel including gas, oil and coal.

Rubber is a unique material known for its elasticity and durability and, as such, it remains one of the most popular materials for many sectors to this day.

From brief to delivery, our experts assess our client’s individual requirements and find the best type of rubber for your application, taking into account budget, period, and, of paramount importance, functionality.

A wide variety of industries, including construction, aerospace, defence and material handling, require anti-vibration solutions to limit noise, vibrations, and shock. GMT specialises in providing anti-vibration mounts and other products to cater for each industry by offering a range of bespoke solutions to protect your equipment, vehicles, machinery and workforce. These products are a necessity for many companies, and without them, the efficiency of a company, its people and its products can be jeopardised.

A rubber compound is produced by adding specific chemicals to raw rubber material in order to improve and alter the characteristics of the rubber for the desired use. Selecting the correct rubber compound is vitally important for any application in any industry, and the best way to do this is to select which rubber compound properties are most important.

In this post, we’re looking at some of the different properties of rubber compounds and how you can choose the right rubber compound for your applications.

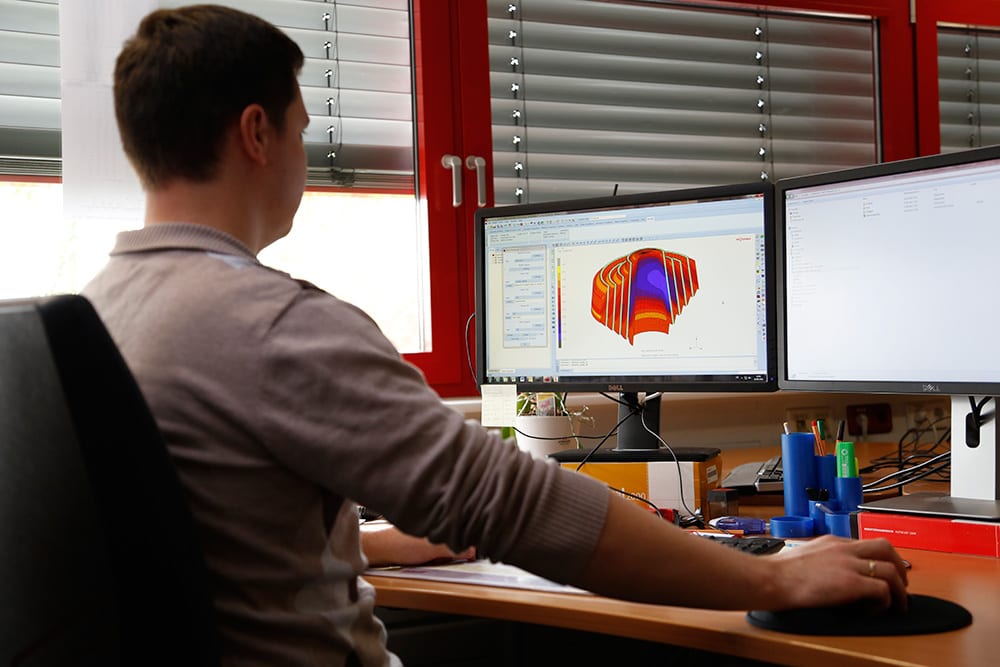

There are many advantages of finite element analysis as a method of product testing for businesses in many different sectors, including aerospace, construction and defence. In this post, we’re discussing the details of finite element analysis and how it works, as well as the benefits of using this testing technique over other methods.

We’ll also look at how it can be used to benefit companies and ensure the best products are being made, including how we incorporate the method with our products here at GMT.

Construction is a noisy business; there’s no way to avoid it. However, there are different classification levels of noise pollution on construction sites, and some are more damaging than others.

Are you aware of the importance of controlling vibrations in construction? Eliminating or minimising the sources of noise pollution in construction is a highly effective way to mitigate risks to workers. However, this is not always feasible, so in this blog we will discuss the industrial noise control regulations and offer some tips on controlling noise pollution on construction sites.

At GMT, we create standard and bespoke rubber bobbins, buffers and bushes, among other things, for various industries and many different uses. These products are all produced using rubber to provide flexibility. One of the key differentials for us is the Shore hardness of the rubber, but what is the Shore hardness of rubber?

This guide will provide an overview of what the Shore hardness of rubber is and how different rubber hardness scales are used to measure it.

An engine mount’s primary purpose is to secure an engine into machinery and absorb any shocks and vibrations when the machinery is operating. Engine mounts and anti-vibration mounts are essential for preventing damage to the engine and improving operator comfort (where applicable). But what happens when engine mounts need replacing? And, do you know the symptoms of worn engine mounts? We answer both of these questions in this post.

Engine mounts are an essential component of your machine or vehicle, connecting the engine to the chassis. They are designed to absorb shocks, vibration and noise during operation, which is crucial for preventing damage to both the motor and the chassis. This post discusses the different types of engine mounts available, their pros and cons, and compares solid rubber vs hydraulic motor mounts.

As a leading specialist in rubber vibration mounts, we offer our extensive expertise using a step by step guide to help you choose the correct rubber mounts. Read on to read our easy to follow guide to choosing the best anti-vibration mount to suit you.

Both natural rubber and synthetic rubber hold an important place within the rubber industry, both in high demand by manufacturers. The difference between natural and synthetic rubber (in terms of how they’re made and their properties) makes both types of rubber useful for different applications. In this post, we look at natural rubber vs synthetic rubber, explaining the differences and the pros and cons of both.

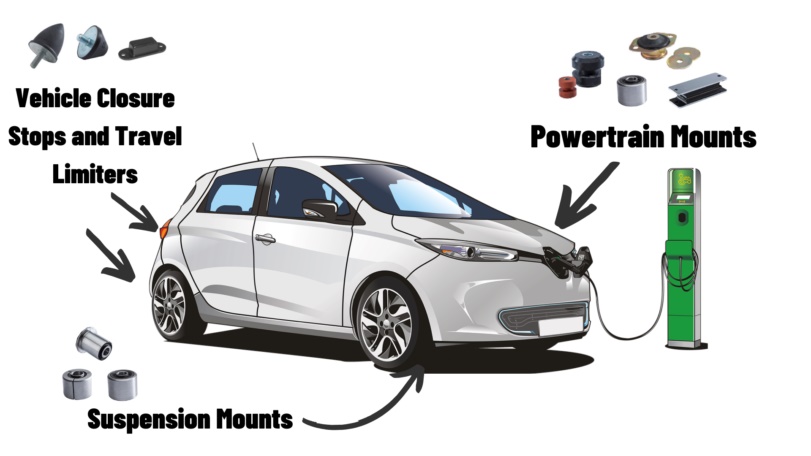

Rubber bushings are effective in reducing the transmission of shock and vibration between parts. In the automotive industry, there are many advantages of using rubber on shock absorbers, including improved safety and comfort when driving, minimised noise and damage due to reduced vibration.

The use of automotive rubber bushes has been credited to Walter Chrysler, an American automotive industry executive. Walter encouraged the adoption of rubber vibration-isolating mounts to cut down the vibration and noise of vehicles. From then on, automotive rubber bushes were adopted for use in many parts that generate vibration and noise, and are now a conventional method across the automotive and commercial vehicle industries.

An air spring system provides a cushion between the vehicle body and wheel to reduce the vibration felt during travel. This blog will explain air spring systems and discuss air suspension advantages and disadvantages, to give you a better understanding of how they work. In particular, it will cover the benefits of air suspension when used in cars, but some of the principles carry over to heavy vehicles like trucks, tractor-trailers and passenger buses and trains.

At GMT, we take our environmental and energy management processes seriously, to ensure we are as environmentally and energy conscious as possible. In order for us to do this, we need to make sure the correct systems are in place so that we can manage our operations efficiently and ensure that we are mindful of our environmental impact.

ISO 14001 and ISO 50001 are two different frameworks that help with environmental and energy management systems. In this post, we describe what both of these frameworks include, as well as discussing their benefits so that you can see the mindful processes we adhere to at GMT without compromising on quality.

In the past few years, there has been a dramatic increase in the recycling of plastics and paper, with more and more people becoming aware of the positive economic effects recycling can bring. But other products can be recycled that people are not as aware of, such as rubber. Recycled rubber products can be used in many ways, but how is rubber recycled? And what are the advantages and disadvantages of recycling rubber? In this guide, we cover all of these questions and explain the rubber recycling process in more detail.

When selecting an anti-vibration mount, it is always important to consider what would happen if the rubber was overloaded due to improper use and the rubber were to fail. In this context, it is useful to be able to categorise mounts as either captive or non-captive. The images below show the fundamental difference between the two.

Originally, in July 2017 the government announced a ban on the sale of any new diesel, petrol or hybrid cars by 2040, in an effort to dramatically reduce air pollution. This comes as a strand of a larger plan to attempt to emit zero carbon by 2050. As such, as of February 2020, the banning of petrol and diesel cars by 2040 was brought forward to 2035 “if possible“.

Many properties of rubber make it the ideal material for anti-vibration products. To conserve these properties it’s important that the rubber is protected from environmental conditions, such as light and heat, that might otherwise degrade it. Consideration should also be given to protecting the metal that the rubber is often bonded to, as this can also be affected by these conditions.

Of all industries, one which undeniably faces the most extreme conditions, and consequently necessitates the use of only the toughest equipment, is the marine industry.

Equipment on marine vessels can be at sea for long periods of time in very low temperatures, constantly exposed to a whole host of extreme weather conditions. What’s more, due to the crucial nature of many roles within the industry, new and innovative marine technology is constantly being developed to ensure these can be fulfilled as effectively as possible. To ensure this technology can perform under such critical conditions, certain measures have to be taken.

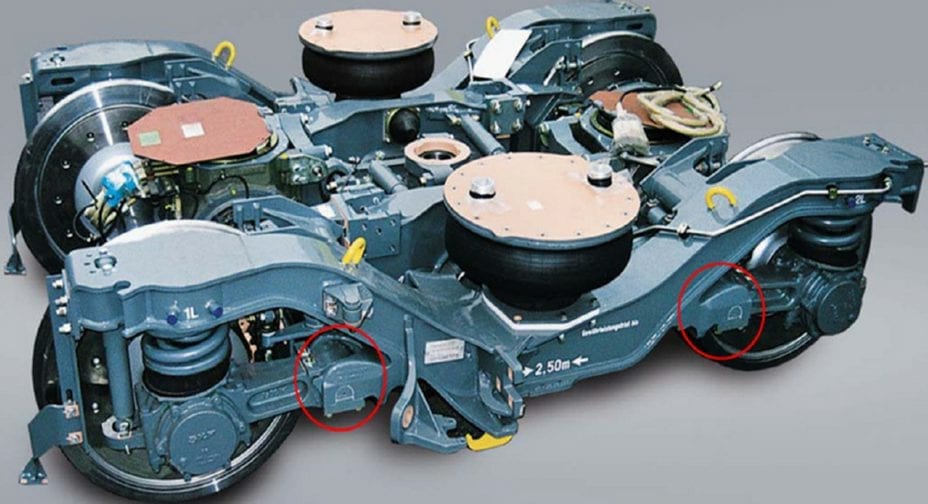

The Department of Transport has released a new report stating that Railways have now become the second most-used mode of transport in the UK, second only to cars. This demonstrates that, as roads have become more convoluted, people are making use of the UK’s rail service more and more. This is especially true for those living outside of a city centre but travelling into it for work. Driving into a city during rush hour normally means adding extra time onto your commute. This means that travelling by train can be a much more convenient and appealing option, but only if they are running efficiently. To keep customers happy, trains need to be consistently on time, comfortable, and able to run efficiently during peak times.

Suspension bushes are a type of vibration isolator that is often made of rubber. The purpose of a suspension bush is to prevent metal-to-metal contact while still allowing for some movement. The movement is essential for allowing parts of the suspension to move freely. Although small, suspension bushes largely influence the efficiency of a vehicle, playing an important role in the safety, comfort, and handling of a vehicle. Due to the constant exposure to the elements underneath a vehicle, deterioration of suspension bushes can occur over time.

It’s therefore important to check your suspension bushes.

Levelling feet can stabilise a wide range of machinery, with the height adjustment feature of allowing machinery to be levelled when installed on uneven ground.

There are a variety of combinations and sizes available, meaning that there is a type to suit all applications. At GMT, spindles can be combined with various types of threaded foot plate, enabling customers to specify feet to their exact requirements. The feet can also be specified to have anti-slip rubber pads. Additionally, feet with high load bearing capacity and self-aligning capabilities are available.

Special software allows us to plan out and accurately represent the object we have in mind. Connecting geometric shapes, curved surfaces, and lines, the 3D model gives a mathematical description of the surface of the object. Here at GMT Rubber, if standard products are not suitable to a client, we are able to produce a new design using 3D modelling. This is used in conjunction with Finite Element Analysis (FEA).

With knowledge of the client’s needs, we build a product to meet the specification whilst ensuring that the finished design is also capable of meeting service life/durability requirements.

GMT’s range of technically advanced variable stiffness hydraulic axle guide bushes have already been successfully implemented for many years on major train manufacturers bogies to provide adaptive levels of stiffness for bogie axles running on tracks. Train operators are also taking advantage of the reduced wear and tear of wheels and tracks to reduce noise and energy consumption and associated track running costs.

GMT’s specialised axle and wheel set protectors for railway cars are proving to be very popular with train manufacturers and operators to avoid damage by ice and stones due to the significant reductions achieved in maintenance and repair costs. Contact GMT now to learn more about these great products.