Compactor Mounts

Description:

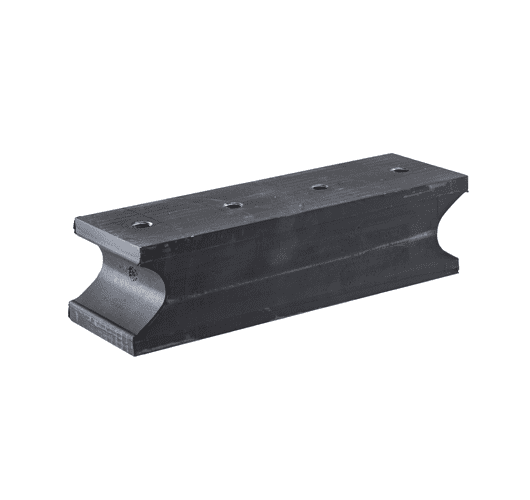

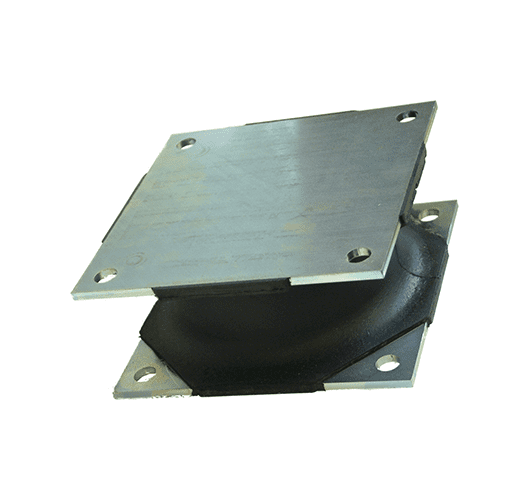

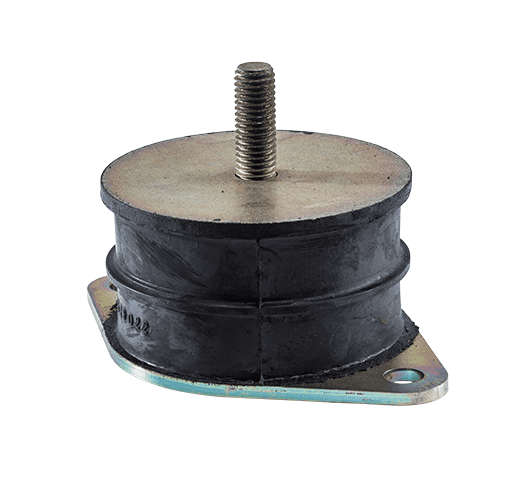

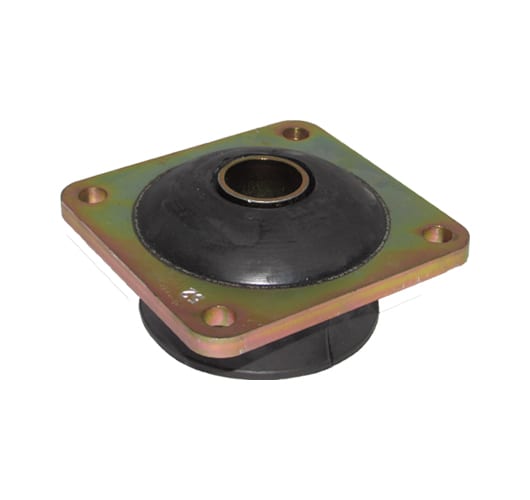

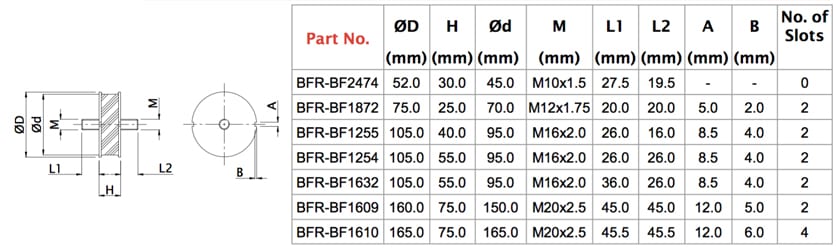

GMT can offer a wide selection of mounts which have been designed specifically for the compaction industry. Our range of products includes plate compactor mounts, roller mounts, waisted mounts and drum mounts, all of which are supplied to major international OEMS for use on walk-behind rollers, ride-on rollers, plate compactors and towed rollers. In this type of application, very high levels of mechanically induced vibration and impact forces need to be isolated. These heavy duty compactor mounts are designed to provide isolation of the vibrating drum or plate whilst preventing wear and fatigue on moving parts. To reduce downtime of machinery, products can usually be offered from stock.Typical Product Dimensions:

Benefits:

The compactor mounts are subjected to very high shear and compression forces. As each type has been designed for a certain application, these maintenance-free mounts offer a long service life. Special rubber compounds have been developed to ensure durability.

Product Codes:

BFR-BF1148, BFR-BF1490, BFR-BF2474, BFR-BF1872, BFR-BF1255, BFR-BF1254, BFR-BF1632, BFR-BF1609, BFR-BF1610, BFR-BF2215, BFR-BF1117, BFR-BF2152, BFR-BF1871, BFR-BF1868, BFR-BF1673, BFR-BF1603, BFR-BF2074, BFR-BF1192, BFR-BF2195, BFR-BF1191, BFR-BF1219, BFR-BF1608, BFR-BF1098, BFR-BF2056, BFR-BF1257, BFR-BF1141, BFR-BF1898, BFR-BF1931, BFR-BF2631, MTG-MTG1210, MTG-MTG1214, MTG-MTG1218, MTG-MTG1227, MTG-MTG1247, MTG-MTG1258, MTG-MTG1367, MTG-MTG1122, MTG-MTG1123, MTG-MTG1124, MTG-MTG1125, MTG-MTG1126, MTG-MTG1127, MTG-MTG2219, MTG-MTG2220, MTG-MTG2058, MTG-MTG1491, MTG-MTG1607, MTG-MTG1851, MTG-MTG1914, MTG-MTG2252, MTG-MTG1150, MTG-MTG1920, 509013, 509028, 505049, 505031, 505042, 505042, 505036, 515073, 510093, 515060, 515055, 510069, 510057, 515058, 505080, 505063, 505066, 505037, 515068, 515031, 515032, 515037, 525056, 515064, 582002, 582001, 582003, 582004, 582005, 582008, 582007, 634000, 634050, 634100, 634200, 634300, 634400, 634101, 634201, 519022, 519014, 809001, 529038, 529060, 822018, 822019 /