-

Rubber Bobbins

Rubber bobbins, also known ...

Stop Buffers

Stop Buffers are designed t...

Buffer Rails

Rectangular buffers can be ...

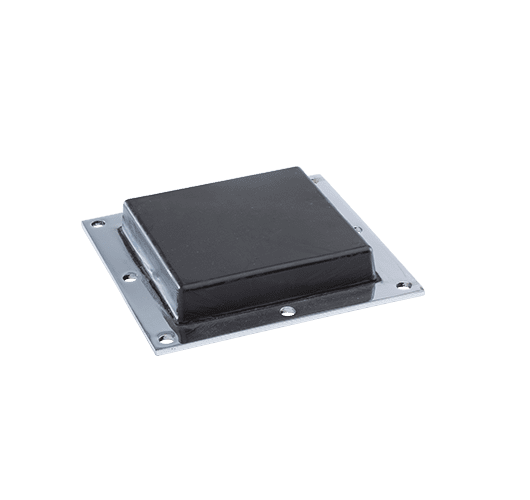

Rubber Pads

Rubber pads usua...

Rubber Buffer Range

There are many types of rubber buffer for each application, and GMT hold a large range of rubber buffer products in stock. Our range includes:

- Rubber bobbins

Available in a range of female and male threads with waisted, hexagonal and profiled in our extensive range.

- Rubber stop buffers

Designed to protect against high-impact shock, these stop buffers are typically constructed from a hard rubber compound for high energy absorption.

- Buffer rails

Can be manufactured in lengths of up to two metres. GMT can cut or drill buffer rails to suit your requirements.

- Rubber pads

Typically, rubber pads use a steel base plate bonded to a rubber section using vulcanisation. Both the rubber and base plate can be customised to your needs.

Rubber Buffer Materials

Our rubber buffers and rubber stop buffers can be manufactured in special rubber compounds to meet specific environmental factors such as exposure to extremes of temperature, oils, acids, solvents and ozone.

Some of the typical rubber compounds that our rubber buffers can be produced in include:

- Natural rubber (standard parts are usually manufactured in natural rubber)

- Nitrile rubber

- Silicone rubber

- Chloroprene rubber

- EPDM rubber

It is also possible to produce this range using different metals, such as stainless steel, or using a special metal finish. See our guide to the different types of rubber for more information.

Bespoke Solutions

At GMT, we pride ourselves on creating ideal bespoke solutions for shock and vibration absorption using our finely-honed design and creation process. If you find that our collection of rubber buffers is not suitable for your needs, then please contact our technical team.