Rubber Mounts

Description:

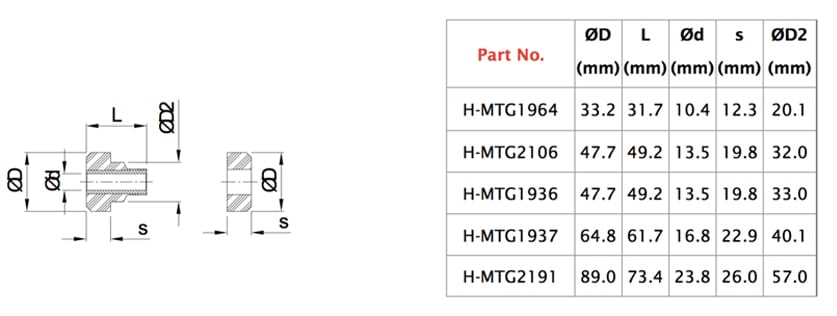

GMT can offer a range of rubber mounts suitable for various applications where a captive solution is required. Their simple design allows for easy installation, and restricts movement in both vertical directions thereby offering a good level of shock protection. Standard rubber mountings are manufactured in chloroprene rubber, which provides good resistance to oils and greases. Other rubber compounds can be offered to suit different environmental conditions.Typical Product Dimensions:

Benefits:

These captive, failsafe rubber mounts provide protection in all three axes. They are typically used in mobile generator and compressor installations, as engine and transmission mountings on automotive applications, and on marine equipment installations.

Product Codes:

H-MTG1964, H-MTG2106, H-MTG1936, H-MTG1937, H-MTG2191, H-MTG1964, H-MTG2106, H-MTG1936, H-MTG1937, T-MTG1676, T-MTG1674, T-MTG1679, T-MTG1682, T-MTG1691, T-MTG1692, T-MTG1697, T-MTG1685, T-MTG1708, T-MTG1692, U-MTG1470, U-MTG1506, U-MTG1246, U-MTG1471, U-MTG1472, U-MTG1473, U-MTG1474, V-MTG1438, V-MTG1439, W-MTG1437, W-MTG1446 /