Air Suspensions

Description:

From our IRIS approved manufacturing facility, GMT can offer a large range of existing air springs and full air spring systems. Alternatively our experienced engineers can design a bespoke air spring system to meet the individual requirements of the application. As an approved supplier to numerous major global OEMs, GMT has gained a reputation for providing high quality products which is imperative for the rail vehicle industry.

GMT's air springs provide high torsional, horizontal and conical displacements, characterising in a low frequency ride which minimises vibration transmission and maximises passenger comfort. They can be supplied complete with additional secondary rubber springs (also known as emergency springs or auxiliary springs), providing further suspension protection in case of air supply defect or leakage.

Typical Product Dimensions:

Benefits:

With the variety of air bellows and auxiliary springs on offer at GMT, we can configure a diverse range of air spring system solutions to suit customer specific applications. Alternatively, full air spring systems or their individual components can be designed to offer a more bespoke solution.

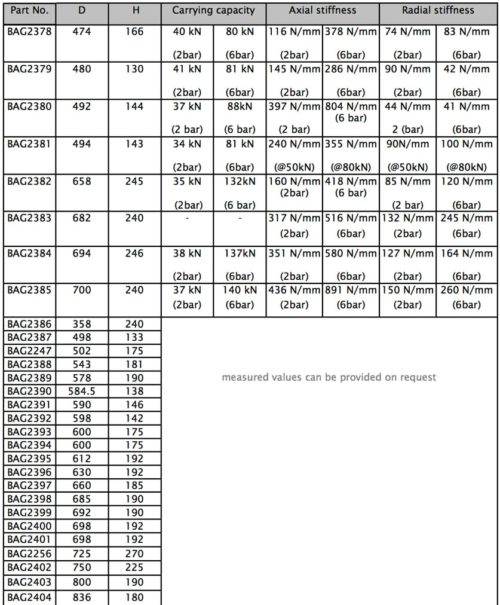

Product Codes:

/