Rubber Bearings

Description:

GMT manufacture a range of rubber bearings such as spherical bearings, which work as mechanical joints in a variety of applications. These include road and rail vehicle suspensions, pivot arms, engine and gearbox mountings and control links. The rubber bearings can be offered in various designs and with different fitment options. Alternatively we can design a bespoke solution if existing products are not suitable for the application.

Typical Product Dimensions:

Benefits:

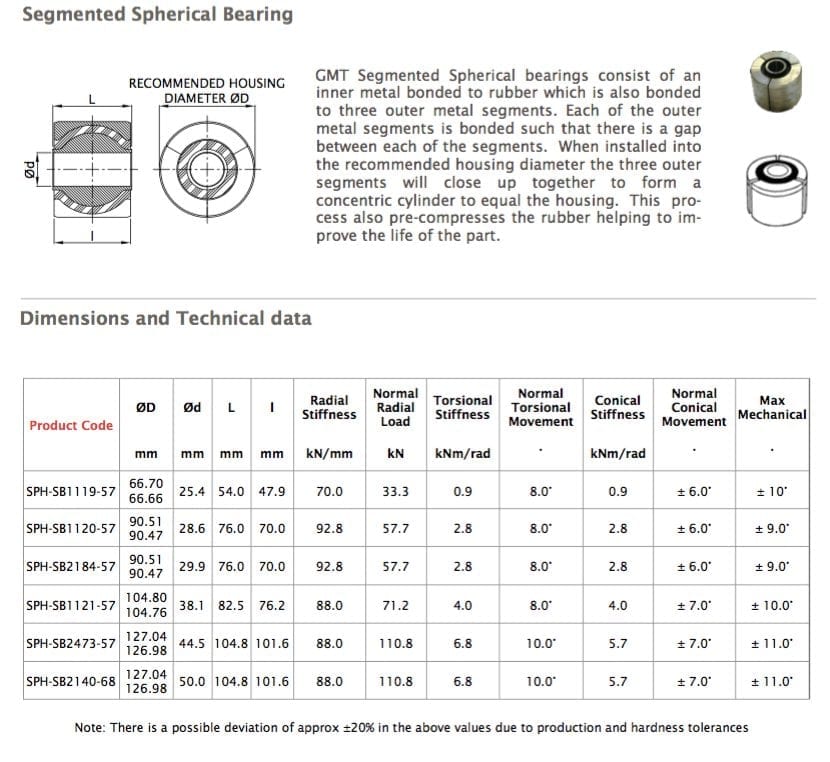

GMT’s segmented spherical bearing design consists of a rubber section fully bonded to an inner profiled metal and to an outer metal consisting of three identical segments. When pressed in to the housing, the three segments close up, thereby pre-compressing the rubber section which helps to improve the life of the part.

Product Codes:

SPH-SB1119, SPH-SB1120, SPH-SB2184, SPH-SB1121, SPH-SB2473, SPH-SB2140, SPH-SB2130, SPH-SB2179, SPH-SB1615, SPH-SB1233, SPH-SB1187, SPH-SB1256, SPH-SB1368, SPH-SB1195, SPH-SB1616, 642002, 642005, 642016, 646001, 642004, 640004, 644044, 641023, 644001, 645001, 641001, 643004, 642006, 643001 /