Chevron Springs

Description:

GMT chevron springs (also known as axle springs) are multipurpose vibration reducing elements, primarily used in the rail vehicle industry. They are both simple to install and easy to maintain. Thanks to their durability, they offer a long service life meaning they are ideal for use in all types of rail vehicle application. By selecting the angle of the steel sections and the number of intermediate steel interleaves, in conjunction with the relative installation angle of the chevron spring pair, three different spring stiffness' can be achieved. Furthermore, the degree of stiffness can also be varied by altering the geometric dimensions of the individual layers, and also by changing the rubber hardness.

Please contact GMT today if you have specific requirement with regard to chevron axle springs. If we can't provide you with a suitable spring from our extensive existing range, our experienced engineering team can design a bespoke solution for you.

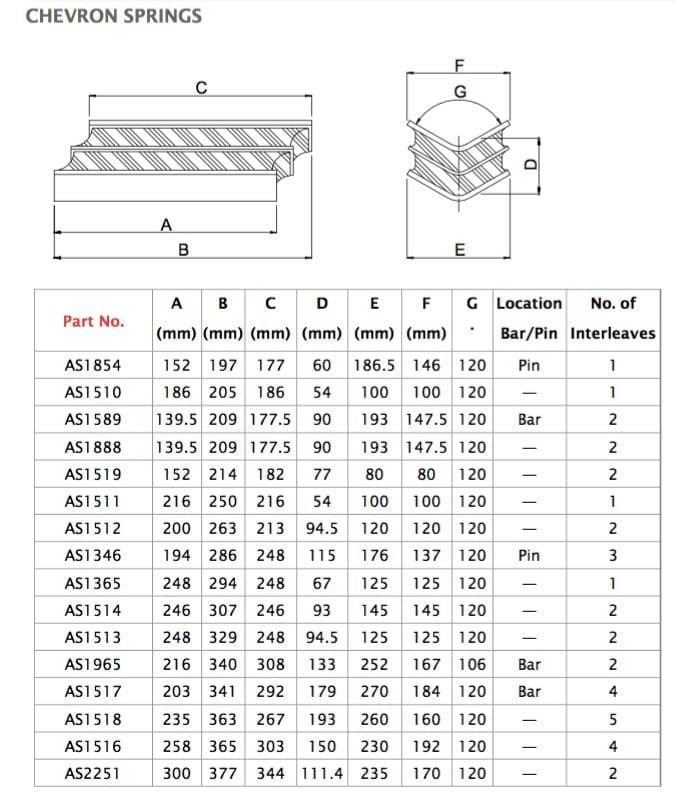

Typical Product Dimensions:

Benefits:

Due to their design, the stiffness characteristics of GMT’s chevron springs can be altered by simply changing the installation angle of the chevron spring pair.

Product Codes:

AS1854, AS1510, AS1589, AS1888, AS1519, AS1511, AS1512, AS1346, AS1365, AS1514, AS1513, AS1965, AS1517, AS1518, AS1516, AS2251, MTG-MTG1210, MTG-MTG1214, MTG-MTG1218, MTG-MTG1227, MTG-MTG1247, MTG-MTG1258, MTG-MTG1367, 601009, 602015, 602015, 602002, 603004, 601006, 602005, 602008, 602027, 582002, 582001, 582003, 582004, 582005, 582008, 582007 /