The Importance of Controlling Vibrations in Construction

There are numerous reasons why controlling vibrations in construction work is important, including the need to keep the construction plans continuing without complaint from the public.

There are various pieces of equipment that can be used on construction machinery in order to help maintain construction vibration limits. In this blog, we will cover the disadvantages of excess vibration as well as anti-vibration techniques and specific product highlights in order to guarantee a reduction in vibrations from construction equipment.

Risks Due to Vibration from Construction Equipment

Health Risks

Exposure to excessive vibrations can cause health risks to workers, including damage to the nerves and blood vessels within the hands. This can result in Hand-Arm Vibration Syndrome (HAVS) and Carpal Tunnel Syndrome (CTS). These two conditions can produce similar symptoms to each other such as pain, tingling, numbness, and loss of strength.

To help avoid these conditions, employers have a duty to minimize employees’ exposure to excessive vibration and are legally bound to comply with the HSE regulation Control of Vibration at Work Regulations 2005. This regulation quantifies two important levels of vibration:

- Exposure Action Value (EAV, 2.5m/s2) – employers must implement operational and technical measures to minimize exposure.

- Exposure Limit Value (ELV, 5.0m/s2) – should not be exceeded in any cases.

Public Complaints

Construction can often generate vibration complaints within the nearby community, despite there being a pre-agreed time limit on the construction between you and those who commissioned the work. It’s important to bear in mind that complaints usually occur when noise and vibration during construction are directly interfering with the community’s day-to-day activities, and often they feel the duration of work hasn’t been made clear enough to them. On some occasions, the contractor can even be seen to be uncompassionate towards the community, regardless of being compliant or not with local regulations.

Early identification and assessment are the best ways for potential problem areas to be flagged initially. The assessment can actually benefit the contractors in terms of making bids for construction plan changes and mitigation costs prior to plans being finalised. Finally, once such an assessment has been completed, a publication that includes a description of the construction vibration level can lead to a much better understanding within the community for the duration of the time construction is taking place.

In addition, it is also worth bearing in mind that when it comes to construction vibration damage to buildings, it is usually seen as the responsibility of the contractor to maintain vibration levels and keep them below damage thresholds previously established by the relevant department.

How to Control Construction Site Vibrations

The types of machinery used in major construction, mining and off-highway industries in particular experience very high levels of mechanically-induced vibration, and therefore impact stresses need to be isolated.

We have been supplying these anti-vibration mounts and other products to these industries for many years, using our experience and innovative approach in order to develop rubber compounds and specialist parts, designed in particular to withhold the pressure created from machines and equipment used within the industries mentioned above. Below are some handpicked examples of some of the anti-vibration products we have designed and how they work.

Isolation Mounts

Isolation mounts are designed specifically to allow relatively high static deflections, enabling isolation against low disturbing frequencies. These are a great way to achieve vibration reduction in ventilation equipment, air conditioning units and heating. Our standard parts for these are manufactured from coloured natural rubber, these are available in different sized and rubber hardness’, to suit each different application.

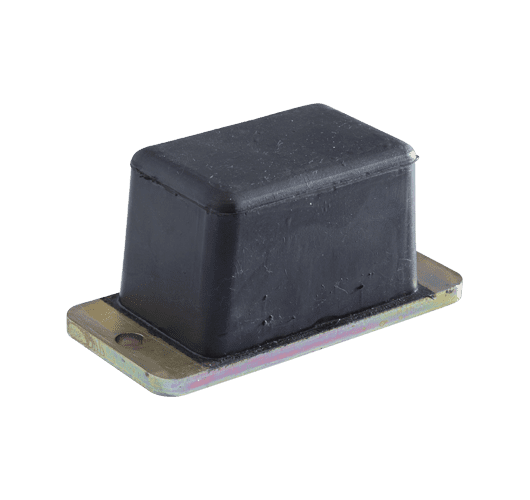

Rubber Dampers

These are used primarily to reduce the transmission of shock to the surrounding structure. This works through the rubber absorber deflecting under the shock load. Also known as rectangular buffers, rubber dampers are made of rubber that has been bonded to a metal plate that featured numerous fixing holes enabling simple installation. As well as this, rubber dampers can be manufactured into a range of different rubber compounds and metal types to suit the necessities of the application.

Compactor Mounts

This range of products has been specifically designed for the compaction industry, these types of applications involve the need to reduce vibration and impacted forces through isolation. Examples of other products in this range include roller mounts, waisted mounts and drum mounts, all of which are supplied to major international OEMs for use on walk-behind rollers, ride-on rollers, plate compactors and towed rollers. Compactor mounts, in particular, are exposed to very high shear and compression forces, which is why special rubber compounds are used to ensure durability.

At GMT, we are leaders in the field of construction vibration isolation. If you require any further information or would like any assistance with purchasing anti-vibration mounts or other bespoke rubber components, please don’t hesitate to contact us today.