Bonding Rubber to Metal

Anti-vibration mounts and shock mounts incorporating both metal and rubber can be constructed either by bonding the rubber to the metal or by attaching the rubber component to the metal component through mechanical means.

In this post, we will go through this unique process in more detail and discuss the process of bonding rubber to metal, as well as some of the advantages of using metal-bonded rubber.

Specifying Rubber and Metal Materials

Different types and specifications of rubber and metal are selected depending on the requirements of the finished part, such as its environmental working conditions and resistance to certain chemicals for example.

Mild steel is widely used due to its cost-effectiveness and availability (although GMT can bond to alternative metals if the need arises), and natural rubber is most often used due to its material properties and commercial advantage. However, different types of rubber compounds can offer more appropriate properties depending on the application/end use.

As different materials have different chemical compositions, consideration must also be made to the most appropriate bonding agent for the rubber/metal combination to be used. This is necessary to ensure that the component functions as intended and performs in an optimised and durable way.

How Rubber Is Bonded to Metal

There are various different methods for the bonding of rubber to metal; for the manufacture of anti-vibration mounts and shock mounts where a strong and durable bond is required, bonding is normally achieved through vulcanization.

The following is a typical process for bonding rubber to metal using vulcanization:

- Preparation of the metals

The metals (mild steel, stainless steel or aluminium for example) are prepared to ensure a clean surface, which is free from oil, grease, and loose material, is available for the rubber to be bonded to. This metal surface is usually degreased and then blast-cleaned in preparation for bonding.

- Application of bonding agent

A two-part bonding agent is applied to the metal surface, consisting of a primer which is dried using hot air driers prior to the application of a cement. The bonding agent can be applied using different methods, such as spraying, brushing or dipping.

- Vulcanisation

The prepared metals are then placed into the mould tooling, and the rubber is vulcanised and cured. A combination of correct pressure, temperature and time during the vulcanisation process creates a chemical reaction of the bonding agent and ensures a successful bond between the rubber and metal.

- Testing

To check that a successful bond has been achieved, tests can be completed on finished components or test samples to verify the strength of the bond.

What are the advantages of rubber-to-metal bonding?

- Ease of fixing

Rubber provides the spring element to allow for vibration isolation and/or shock protection, but it is the metal components that allow the rubber springs to be fastened in place. Bonding the metals to the rubber allows for various fastening methods, such as threaded fasteners or mounting plates with fixing holes.

- Easier to create captivity for enhanced safety

Rubber-to-metal bonded parts can be designed such that the bond between the rubber and the metals holds the part together but with additional captivity provided by the metal sub-components. This captivity ensures that, should the rubber be overloaded and fail, the metal sub-components continue to hold the parts together.

- Design for stiffness

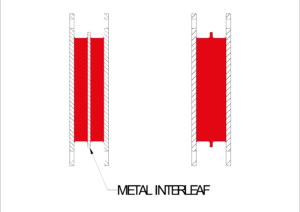

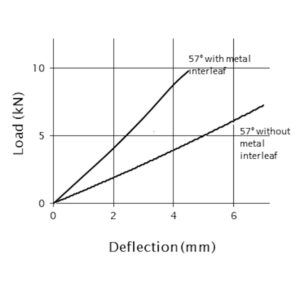

By bonding metal to rubber, different designs can be achieved which provide different stiffness characteristics. Sandwich mounts, chevron springs and bolster springs often have one or more metal interleaves, increasing the compressive stiffness of the part relative to a part of the same dimensions.

Example of the effect on compressive stiffness through adding a metal interleaf:

Bonding Rubber to Metal with GMT

At GMT, a large proportion of our products incorporate a rubber-to-metal bond. Non-captive parts, such as buffers, rely only on the rubber-to-metal bond to hold the part together whereas captive parts, such as cone mounts, incorporate a mechanical locking mechanism which acts in conjunction with the rubber-to-metal bond to hold the part together.

We can bond to mild steel or alternative metals such as sea-water-resistant stainless steel or low-weight aluminium if required. Alternatively, we can apply various types of coating to the bond-free areas of the metalwork to provide protection against different levels of corrosion.

With over 55 years of manufacturing experience, at GMT, we understand the importance of considering a strong bond between rubber and metal at the design phase, and carrying this through to production.

Please contact us today for more information or advice about bonding rubber to metal and take a look at the technical guides on our blog for a glimpse into our processes and expertise.