How to Choose the Best Rubber Compound for Specific Applications

A rubber compound is produced by adding specific chemicals to raw rubber material in order to improve and alter the characteristics of the rubber for the desired use. Selecting the correct rubber compound is vitally important for any application in any industry, and the best way to do this is to select which rubber compound properties are most important.

In this post, we’re looking at some of the different properties of rubber compounds and how you can choose the right rubber compound for your applications.

Rubber Compound Properties

Every application of rubber compounds is different, and each requires different properties. However, natural rubber is the preferred choice for many applications as it often provides the best dynamic properties overall. In addition, additives can be used to improve characteristics such as resistance to ageing.

Synthetic rubbers can also be mixed with natural rubber to create hybrid rubber compounds, and these can benefit from the shared characteristics of each type of compound.

You can learn more about the differences between natural and synthetic rubber over on our blog.

Some of the most important rubber compound properties include:

- Hardness – you can measure rubber hardness using the Shore hardness scale.

- Temperature resistance – resistance to temperature extremes can be very important for certain applications.

- Tensile strength – this refers to the amount of force needed to break the rubber by pulling it apart.

- Elongation – when tensile force is applied, the elongation is how far the rubber will stretch, measured in the percentage change of length before breaking.

- Abrasion – if the rubber compound will be used for an application that has a lot of abrasion, like rubbing or scratching against the surface, it must be able to stand up to that abrasion.

- Flexibility – this can be an important rubber compound property, as flexibility might be a necessity or could hinder the component’s functionality.

- Resistance to different conditions or materials – heat, light, oxidising, ozone, wear and tear, chemicals, acids and water, among others, are all things that are key to choosing the right rubber compound.

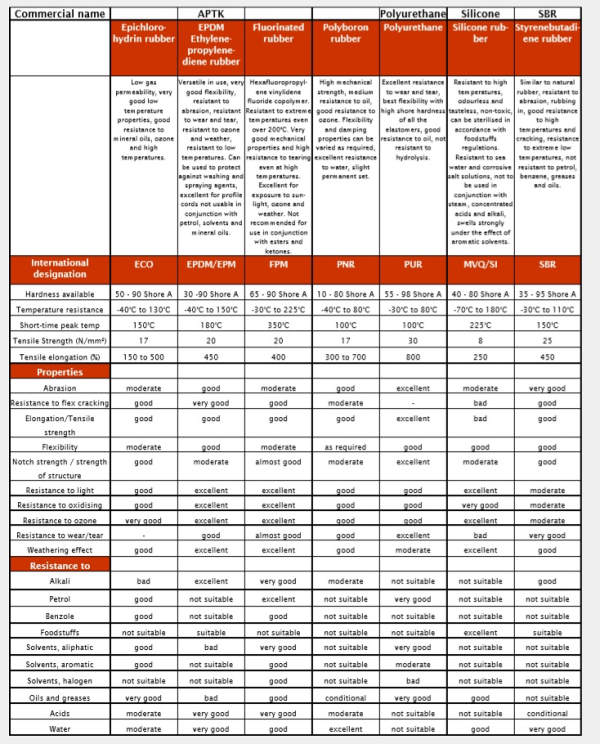

The following table can be used as a guide to help you select the preferred rubber compound for a particular application.

Uses of Rubber Compounds

Rubber is used in innumerable industries and in the creation of thousands of products. If you’re unsure which rubber compound to use, talk to our team, who will be more than happy to help you.

However, here are some examples of how rubber compound properties play an important role in choosing the right rubber compound.

- Automotive rubber compound application

The automotive industry is the largest global rubber user, with tyres making up the bulk of that usage. For automotive applications, the presence of chemicals such as oil and petrol calls for natural rubber to be physically protected, often by a metal cap.

However, another challenge in an automotive assembly is that the products must be designed for high temperatures as it is not always possible to shield natural rubber from these temperatures, even after undertaking the usual techniques of cooling or remote placement.

In these instances, nitrile rubber (NBR), fluorinated rubber and silicone are preferred due to their heat resistance. Silicone rubber also displays excellent resistance to low temperatures, while fluorinated rubber has good resistance to water and oils, and excellent petrol resistance.

- Marine rubber compound application

For submerged marine applications, chloroprene or neoprene is often used due to its good resistance to saltwater. Where there is a lower level of salt spray, natural rubber can sometimes be used, often with additional spray protection by a cover or sealed unit.

For more information on the marine industry and using the correct components for protection against conditions at sea, check out our previous blog post.

Why choose GMT Rubber?

There are many types of rubber, and at GMT, we have a wealth of experience in selecting and manufacturing the right compound to suit customer requirements. Using our in-house automated mixing systems, we can ensure that the correct formulation is produced based on the many thousands that GMT has developed.

All batches of rubber produced by GMT are computer-controlled and 100% tested prior to being accepted for production, including using finite element analysis software to test for as wide a range of conditions as possible. This ensures traceability through to the finished product and successfully identifies the suitability of the rubber batch against the customer’s requirements.

GMT have over 50 years of experience in identifying and selecting the correct rubber compounds to meet the requirements of our customers, even in the harshest of applications and operating environments.

If you would like information or advice on what rubber compound will suit your application or what rubber compound properties will be the best fit, please contact us today and our technical sales team will be happy to help. For more technical guides, please see the rest of our blog.