-

Stop Buffers

Stop Buffers are designed t...

Rubber Springs

Rubber springs are availabl...

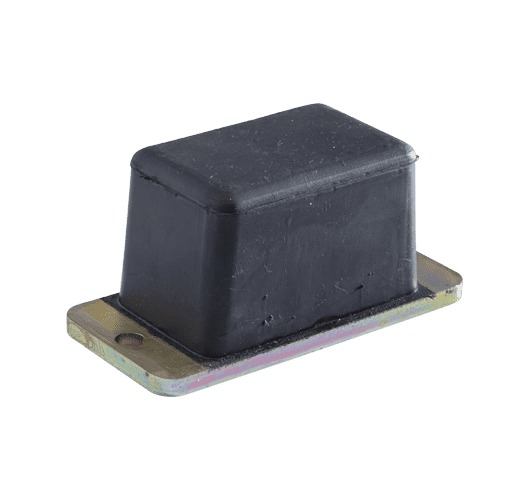

Rubber Dampers

Rubber dampers o...

Wire Rope Mounts

The multi-directional cable...

Why Are Shock Mounts Used?

The purpose of a shock mount is to reduce the level of transmitted shock to the surrounding structure through relatively high deflections in the rubber.

Shock mounts are typically used in different applications to anti-vibration mounts (although products may overlap): where vibration mounts may be used in applications with low-level but frequent vibrations, shock mounts better protect against sudden, larger impacts.

Uses and Applications

Examples of shock mounting applications include bumpers on commercial vehicles, crane buffers and military applications (to military-standard shock specifications where required). They can also be used to ensure the efficacy and reliability of marine vessels and equipment, or in the manufacture of aircrafts.

GMT Shock Mounts

- Stop Buffers: Produced in hard rubber, these are ideal for high energy absorption. Standard parts are manufactured in natural rubber 71° Shore A.

- Rubber Springs: Rubber spring suspension is ideal for shock applications as it can hold considerably more weight, compared to other spring materials. Our rubber springs can be supplied with a metal insert for easier installation and the hollow centre allows for high load performance.

- Rubber Dampers: These are ideal shock mounts as the rubber absorber deflects under an applied shock load. They are bonded to a metal plate which has fixing holes for easy installation.

- Wire Rope Mounts: Created with stainless steel, these shock mounts are perfect for hostile environments and certified to military shock standard MIL-S-901. The captive design also means they can be loaded in any direction.

Bespoke Isolation Mounts

If you are in need of non-standard or bespoke rubber shock mounts, please do not hesitate to contact us at GMT. Our team is highly-experienced in creating custom anti-shock solutions to ensure your machinery, equipment or vehicle is optimised through our tried and tested process.