How to Meet Industry Standard Isolation Levels by Choosing the Correct Vibration Control Products

GMT mounts are used to isolate against two main types of mechanical movement; vibration and shock. Put simply; vibration is described as a repeated movement, whereas shock is a one-off disturbance.

This blog will only consider vibration; shock isolation will be discussed separately. Although it is vibrating machinery that we are discussing, customers who wish to isolate a body against an external vibration will also be able to follow this process, as it is fundamentally the same.

Mechanical isolation is a complex topic with many facets to consider; therefore, the following discussion is intended to provide an overview of the fundamentals only. Should you require help assessing your specific application, please contact GMT and we will be happy to assist.

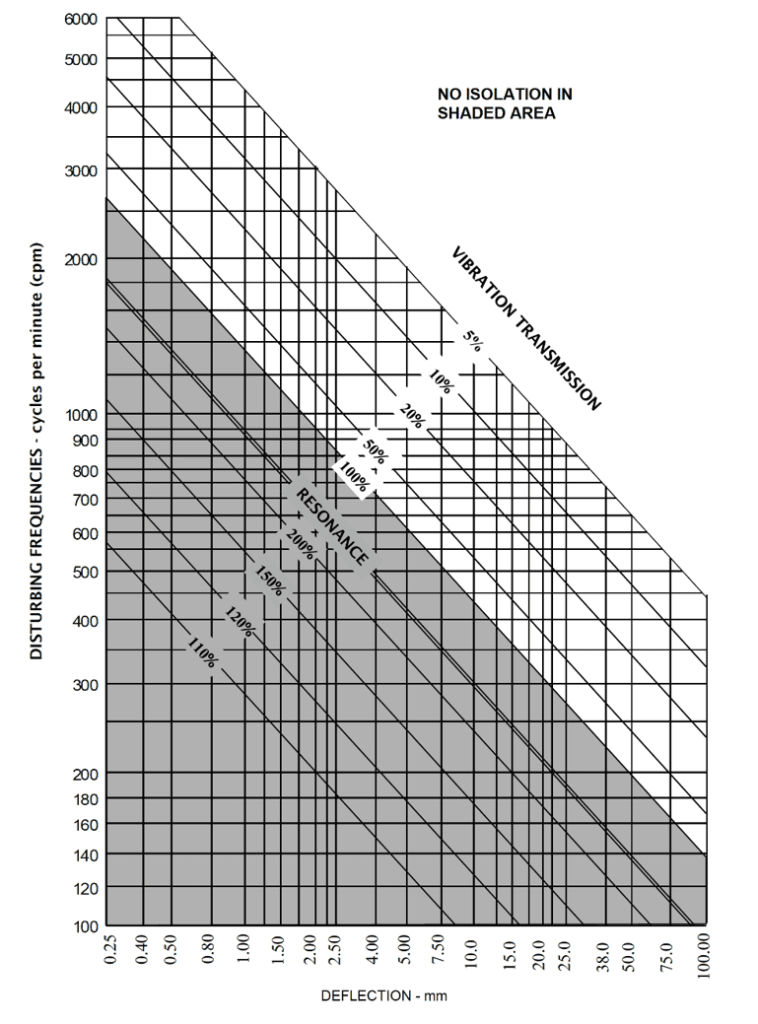

Vibrating machinery should ideally be isolated completely, eliminating all transmitted vibration to the surrounding area. In practice, this is not possible, and a minimum level of isolation is strived for. The following graph shows the relationship between the vibrating or disturbing frequency, the deflection of each mount under the static load, and the level of vibration transmitted to the surrounding support structure.

This fundamental relationship forms the basis of selecting the correct amount of deflection for vibration isolation, and to use it the following application information must be known:

• The lowest disturbing frequency of vibration

• The weight supported by each mounting point, i.e. the static load

GMT uses this information, along with other aspects of the application (see our blogs on rubber compounds and hardness) to select mounts which will deflect enough under the static load to provide a ‘reasonable level’ of transmission. The exact level is based on GMT experience and the customer’s requirements or expectations.

Worked example

Problem

A static machine with a running speed of 1400RPM weighs 1000kg spread evenly over 4 mounts, and the customer has requested 70% isolation i.e. 30% transmission.

Solution

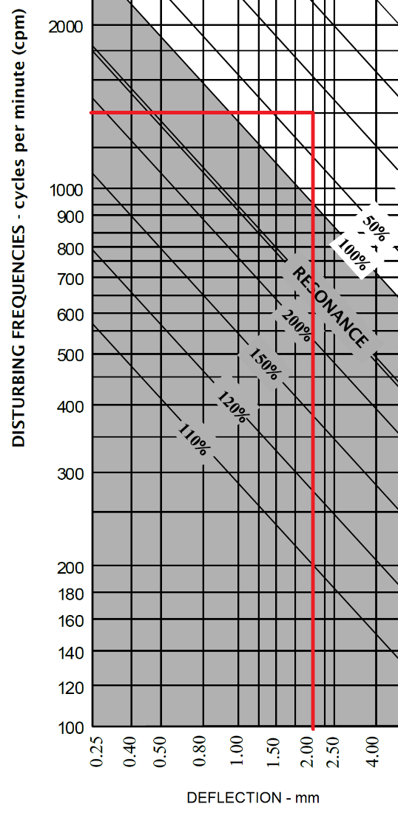

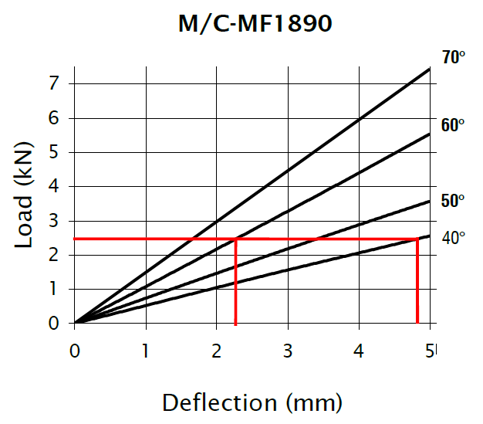

From the graph opposite, 1400RPM requires around 2mm static deflection of each mount to achieve 70% isolation. Each mount will support 1000kg / 4 = 250kg = 2.45kN.

There are a few types of isolator that may be suitable for this application. For the purposes of this example, we have chosen M/C-MF1890 in a 60° Shore A hardness which will deflect around 2.3mm under this load (with a stiffness of 1.07kN/mm). Using the transmission graph, this will provide isolation in the region of 75% (25% transmission) which meets the requirement.

The 40° Shore A variant could also be used which would provide 4.8mm static deflection and around 89% isolation against the 1400RPM disturbing frequency. Please note that care would need to be taken in selecting this hardness because the 4.8mm is close to the recommended 5mm static limit. Therefore any increase in engine weight could cause too much static deflection.

For more information on GMT’s isolation products and vibration control products, please visit the main page of our website where you can browse our entire range. Or, please get in touch for more information on all our products.