The Advantages of Finite Element Analysis

There are many advantages of finite element analysis as a method of product testing for businesses in many different sectors, including aerospace, construction and defence. In this post, we’re discussing the details of finite element analysis and how it works, as well as the benefits of using this testing technique over other methods.

We’ll also look at how it can be used to benefit companies and ensure the best products are being made, including how we incorporate the method with our products here at GMT.

What is Finite Element Analysis?

Finite Element Analysis (FEA) is a computerised technique that predicts how products and materials will react to forces in the real world, alongside other physical effects like vibrations, heat, and fluid flow. This is important as it demonstrates whether a product will work or fail. If a product won’t hold up to the conditions in which it will need to function, then it needs to be reviewed – the advantage of using finite element analysis is that you won’t already have produced the product at this stage.

How finite element analysis works

For finite element analysis to work, it is necessary to break down an object into

thousands of smaller constituent parts, often referred to as ‘finite elements’. In general, the more elements there are, the finer the ‘mesh’ and the more accurate the model and results will be. Too many elements, however, will result in time-consuming (and therefore costly) computer processing for no discernible improvement to accuracy.

With complex mathematical equations, it is possible to accurately predict how the product will react to different simultaneous inputs. Thanks to advances in computer software and computer processing power, these calculations can be carried out using this method accurately and quickly.

Advantages of Finite Element Analysis

There are numerous benefits to using finite element analysis for product testing.

- Safer testing conditions

One of the great benefits of finite element analysis is that it allows for the safe simulation of conditions that may be dangerous or difficult to replicate in a physical test environment.

- Detailed results

The results produced by FEA software are extremely detailed and accurate, offering a wide variety of conditions to test against. This is an advantage of finite element analysis over other methods, as it goes further to ensure the safety and efficiency of each product produced.

- Efficient

This technique also saves a lot of time, as doing the analysis by hand or inflicting the conditions to test the product in person would be extremely time-consuming.

- Versatile

Once you have invested in the software, finite element analysis is beneficial as it can be used for an endless number of products.

- Cost-effective

Although there is the upfront cost of buying the software, it is versatile and can be used frequently for many types of products, constantly helping a business keep its costs down and create products of the highest quality.

Importance of Finite Element Analysis

Time and money are precious commodities to any business, and the advantages of the finite element analysis method mean that time, effort and costs are saved. In addition, improved efficiency and accuracy prevent expensive mistakes; without using this method, there is the risk that products will not perform as they are intended.

For other guidance on using the right products for your application, have a look at our previous blog post on selecting the right rubber compound and step-by-step guide to choosing anti-vibration mounts.

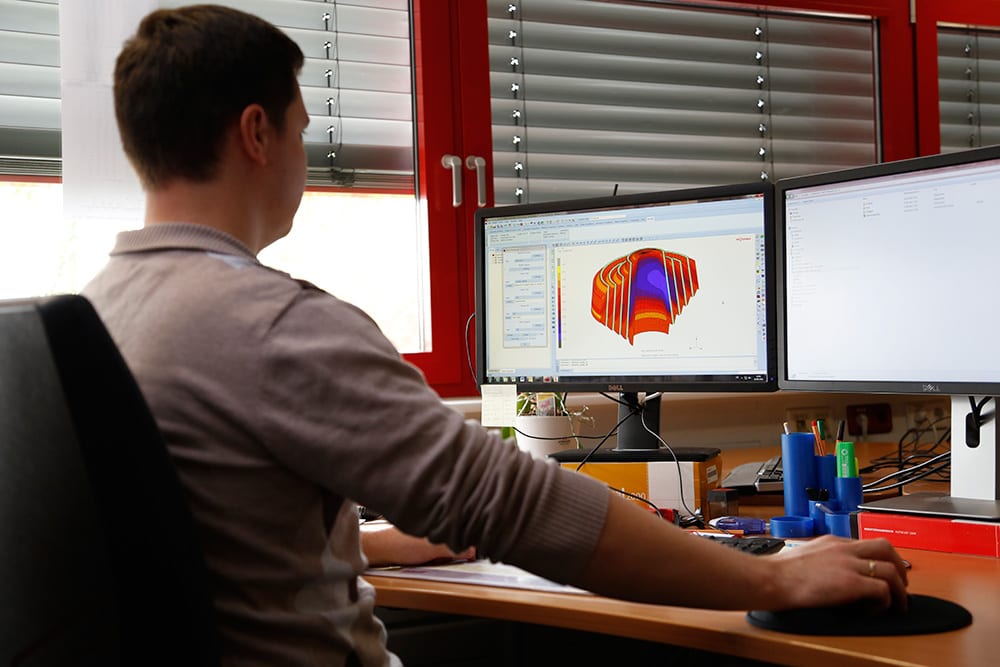

How GMT Uses Finite Element Analysis

At GMT, finite element analysis plays an important role in our design and application process. We use a complex and reliable software that incorporates an accurate simulation of how the materials in our products would behave under different conditions, and we use this software for non-linear analysis of the rubber behaviour.

The software ensures accurate modelling of the products we design and supply by allowing us to place product designs through a variety of different load cases and frequencies. In this way, we ensure that customer specifications can be met whilst ensuring each product’s durability and lifespan are maintained.

We have thousands of existing products for customers to choose from, but through the use of finite element analysis, we are able to offer optimised and bespoke solutions to our customers. Designed to meet customer requirements, finite element analysis reduces the time required for us to produce these products.

The advantages of finite element analysis make it an ideal process for ensuring the safety and durability of your products. If you require bespoke products or would like any advice on finding the right product for your requirements, please do not hesitate to contact us today.