Aerospace Mounts

Description:

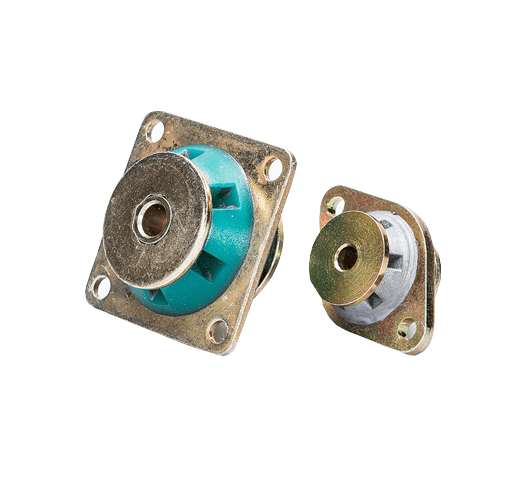

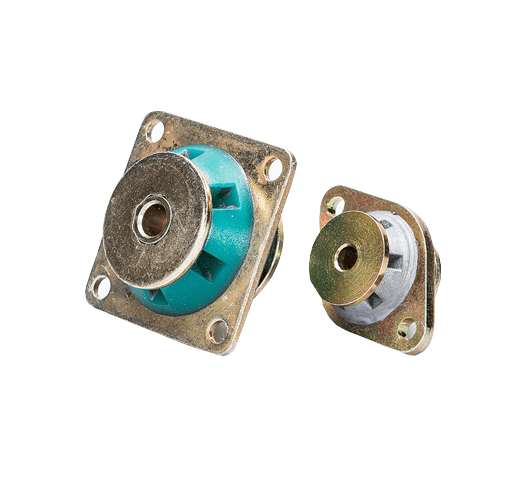

GMT supply a wide range of specialist rubber mounts for aircraft manufacturers. Our elastomeric MF shock mounts can be used to mount all kinds of electrical and mechanical components inside the plane such as instruments in the cockpit, air conditioning units, electrical components for flight control or pumps and gear drives on the jet engines.

GMT also supply shock mount systems for prevention of intrusion through the cockpit door. These elements absorb the attempted intrusion and thus protect the locking mechanism effectively. Overhead compartments are also mounted using GMT products. Their correct mounting in the plane is of great importance as these hollow containers increase existing vibrations. The overhead compartments are therefore isolated against vibrations with the help of GMT shock mounts.

To provide aircraft crew members the opportunity of a restorative sleep in the cabin crew rest compartment, it is necessary to keep the noise inside the plane at the lowest possible level. Rubber metal parts are particularly convenient for this purpose as they greatly reduce the acoustic noise generated by the jet engines as well as flow-generated noise.

Benefits:

Aircraft incorporating GMT shock-absorbing products enjoy optimized levels of refinement and comfort. Not all aircraft are fitted with GMT products, so there are certainly differences that you can hear and feel during flight. Over recent years GMT have developed several new components that have set the benchmark for aviation standards amongst respected airplane manufacturers. You will find many of these components in our catalogue.