What Is the Shore Hardness of Rubber?

At GMT, we create standard and bespoke rubber bobbins, buffers and bushes, among other things, for various industries and many different uses. These products are all produced using rubber to provide flexibility. One of the key differentials for us is the Shore hardness of the rubber, but what is the Shore hardness of rubber?

This guide will provide an overview of what the Shore hardness of rubber is and how different rubber hardness scales are used to measure it.

What Is the Shore Hardness of Rubber?

Named after Albert Ferdinand Shore, who both defined the scale of rubber hardness and developed the Shore durometer to measure it, Shore hardness is a measure of a particular material’s resistance to penetration or indentation. For rubber this involves measuring the surface hardness using a Shore hardness durometer as explained below.

Why Does Rubber Hardness Matter?

The rubber hardness of an anti-vibration mount is a critical design factor used in order to provide appropriate isolation. The hardness of the rubber directly impacts the ‘stiffness’ of a part, ultimately affecting how a component will perform in the application.

Identical components can be produced in very soft to very hard rubber, using the same metals & mould tooling. This flexibility allows the engineer to select the appropriate rubber hardness for the component and the application, taking into consideration the load to be supported and the frequency to provide isolation against.

Isolation is defined by the level of reduction of vibration passed between the oscillatory system and its surroundings. For example, anti-vibration mounts act as an isolator and, as a result, minimise the level of vibration transmitted from an oscillatory system to its surroundings.

See our blog post on natural vs synthetic rubber to see how each type’s hardness differs.

Rubber Hardness Scales of Comparison

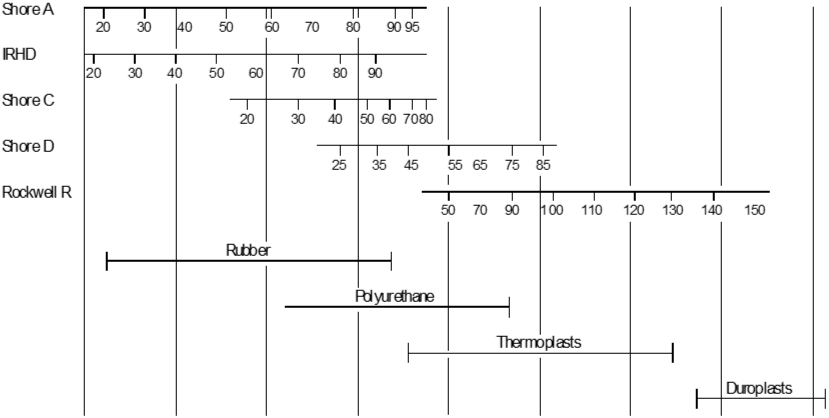

There are several scales to measure the hardness of an elastomer, used for materials with different properties. Two such scales, using slightly different measurement systems, are the Shore A and Shore D scales.

The Shore A scale measures the hardness of softer materials, such as rubber, while the Shore D scale is used for harder, less elastic materials such as certain plastics.

The Shore A scale, used by GMT, is the most prevalent, with typical readings ranging from 20 to 95 degrees, as indicated in the diagram below.

Measuring Rubber Hardness

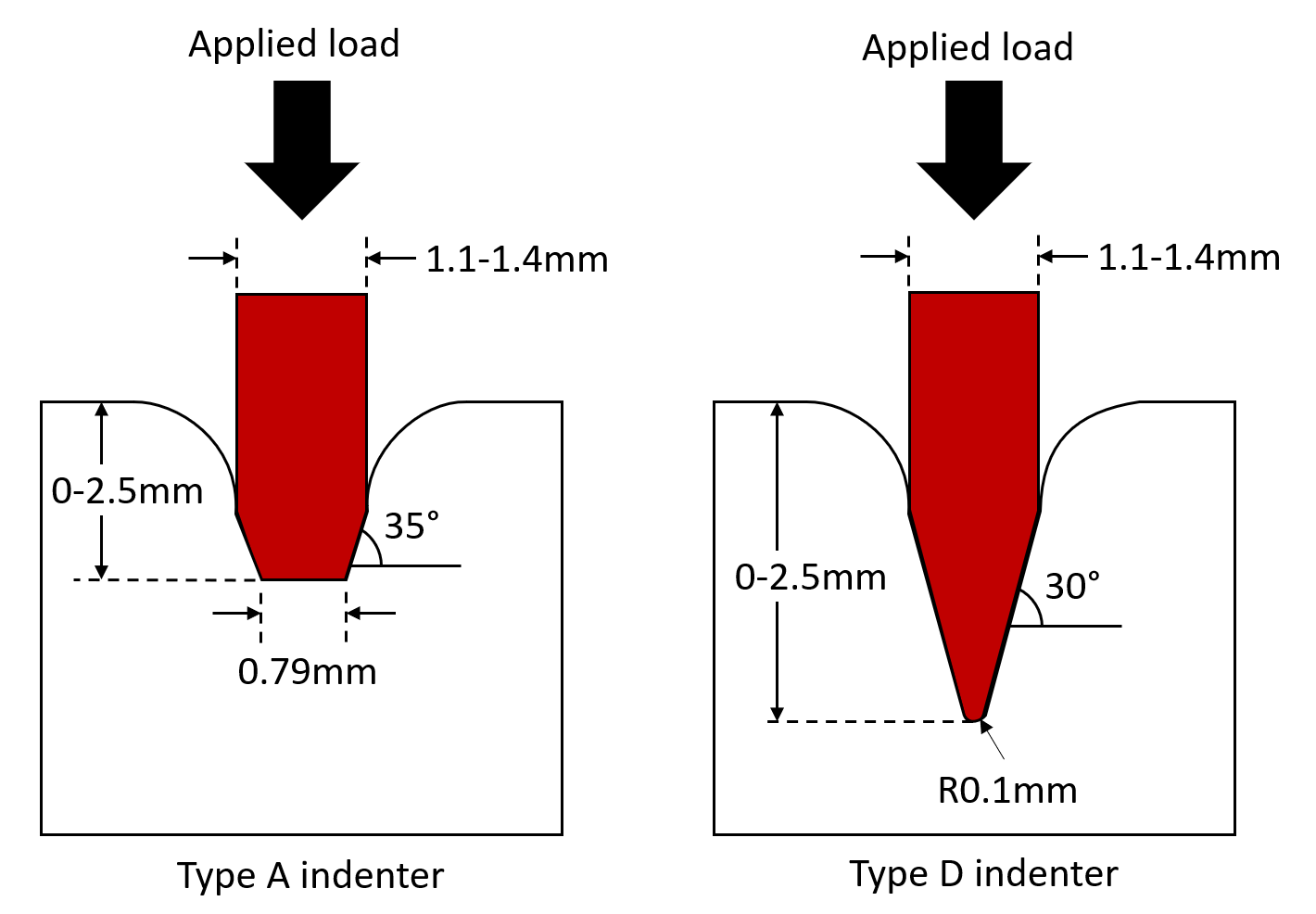

The Shore hardness of rubber is measured with a spring-loaded indentation device known as a Shore durometer. Each Shore durometer has a truncated cone indenter, which is pressed onto the rubber sample. The depth of the indentation is transmitted to a spring within the dial gauge of the durometer, which gives the hardness value.

Every 0.001 inch of deflection of the indenter is shown as one degree Shore (A). Therefore, the harder the material, the lower the deflection and the higher the number overall. For harder elastomers (such as those on the Shore D scale), a more pointed conical indenter is used which will penetrate the test surface, as reflected in the diagram of a durometer hardness test below.

Correction Factor

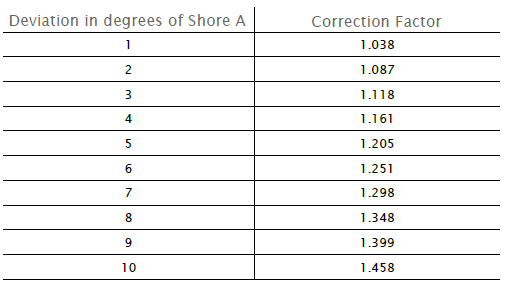

As part of the development process, if a component hasn’t already been manufactured in a specific hardness, the engineers can use the test data of a known component and a correction factor to obtain theoretical stiffness characteristics. This is just one of the many ways GMT engineers utilise their expertise to assist customers on a day-to-day basis.

We hope you now have a better understanding of what the Shore hardness of rubber is and why it’s so important to get it right. If you have any further questions regarding rubber hardness and its suitability in applications, please feel free to contact us at GMT. If you are at the start of the rubber selection process, please check out our guide on choosing the best rubber compound for specific applications, or keep reading our blog for more expert tips on rubber compound selection and components.